Rebar can be a basic steel bar or block which happens to be greatly made use of in strengthened concrete and strengthened masonry buildings. These rebars generally are made from carbon steel and will be recounted as reinforcing steel or simply reinforcement. Under Structural BIM Services Rebar detailing might be a discipline of producing fabrication or shop drawings of steel reinforcement for that building approach. The site fabrication drawings which are produced Based on structure drawings for reinforcing steel are Rebar In depth drawings. Engineers and Architects make design and style drawings to bring about the necessary strengths dependant upon the rebar detailing giving you with diameter, bar designs, quantities, size of bars to facilitate the Website for staying away from delays and wastage thereby rushing your entire construction approach.

Each and every rebar is comprehensive representing a form, size, and diameter based on the necessities Along with the style drawing. The Rebar placement will probably be revealed in more detail which suggests the concrete deal with, correct area, and Specific procedure of placement as needed. The rebar specifics and bar bending schedules will exhibit bar diameter, bar notation, the amount of bars, excess weight from the bars, and duration of Each and every bar Along with mentioning the entire weight for the full set of bars put within the drawing. During the preparing of rebar details, the inventory lengths of bars are saved in see to make certain that There's no wastage during the content.

Rebar Detailing and Reinforcement concrete detailing can now be modeled and designed in three-dimension whilst working with 3D Modelling technological know-how like BIM Modelling Providers. The specialized rebar detailing application like Rebar CAD and AutoCAD employed for this objective should help each member While using the structural engineering to prepare designs, doc, track, and Over-all Manage.

Obtaining understood the necessary Idea of rebar detailing a place of structural BIM modeling, allow for us to make an effort to see the need for it in the general design approach is. Some in the reasons are:

Importance of Rebar detailing in Structural BIM Modeling

Though 2nd drawings and bending schedules tend to be produced and presented, the 3D design is Moreover issued to all or any they customers ranging from the consulting engineer and contractor departments into the steel fixers which happen to be with the stroll out on-web-site. The mixture of your two develop into In particular handy for web page staff where internet site limitations or congestion of reinforcements remain unidentified until you'll find reinforcement and fixation on web-site. For each bar, the particular posture of correcting is demonstrated inside the 3D product Besides any hindrances or obstructions.

Generating detailing reinforcements in 3D throughout the 2D procedure is not merely quicker but modeling rebar inside the three-dimensional environment will help take out clashes. Even though modeling It really is possible to visualize if any within the bars will not repair for the determined place, thereby identify These types of clashes inside of rebar drawings. There is certainly perhaps the facility to evaluate the reinforcement in entire detail being a precise detail illustration ahead of it is remaining requested while in the fabricator and sophisticated cages are assembled off-web page.

When you'll discover the ideal rebar detailing solution accessible, a competent and exact reinforcement model is often accomplished by importing structural calculations from a structural Examination application. With Automation associated the modifications are quickly reflected in the 3D rebar detailing together with needed updates to drawings and schedules swiftly when modifications are established in other places as opposed to acquiring to execute handbook changes to 2D sections and views.

As opposed to based upon manual enter from paper schedules, the rebar fabricator can extract information immediately throughout the design for that equipment. The concrete pours might be very well-outlined within the product together with other aspects like portions and volumes to be sure more accuracy in running material deliveries. This will permit larger Command and cause less wastage and reducing of Total charges.

Having 3D comprehensive digital types will not likely prohibit the power having a solitary-section like that Using the engineering and detailing period but might be used in all the phases. Acquiring reinforcement absolutely modeled in 3D, the contractor is confident that it will fit in parts once the time will come so that it's set on-site. The information from your product may be applied inside the subject to allow for contractors to carry out a design-dependent format by using robotic whole station products along with tracking rebar and products and identifying place they are going to be required.

Fixers present on-internet site can glance inside product setting for that rebar detailing to accurately understand its application, i.e. what exactly is demanded where and when as opposed to relying on their interpretation of regular 2D drawings.

The structural engineers can readily and much more quickly create style and more info design stories, schedules, and drawings from your 3D design in comparison with 2D models, therefore improving style performance. There is certainly a lot more accuracy in Expense projection depending on the rebar portions created from the 3D product as is additionally extra trustworthy when compared to the 2nd drawing choose-offs. Not just this the quantities are absolutely traceable, permitting comparisons and checks to be conducted effortlessly.

Using these explanations, we can certainly conclude that Rebar Detailing a self-discipline of Structural BIM Modelling Expert services is but a single Using the essential standards into the Over-all accomplishment in the venture everyday living cycle. To summarize, having Rebar Detailing the rebar contractor can concentrate on creating rebars there will be no need to estimate reinforcement requirements for procurements at the positioning on account of effective 3D products. The product will depict the necessity for anchors and laps inside of drawings thus ensuring structure adequacy along with minimizing wastage. The overall waste and time delays are lessened at the internet site since all the form drawings will often be out there. Determined by this facts the bars might be simply fabricated based on the designs and amount of bars demanded.

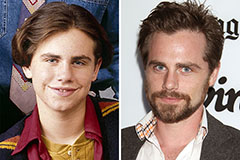

Rider Strong Then & Now!

Rider Strong Then & Now! Julia Stiles Then & Now!

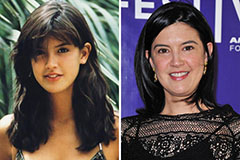

Julia Stiles Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now! Terry Farrell Then & Now!

Terry Farrell Then & Now!